menuProduct Center

backtrackYour locations:Home → Producs → Aging line

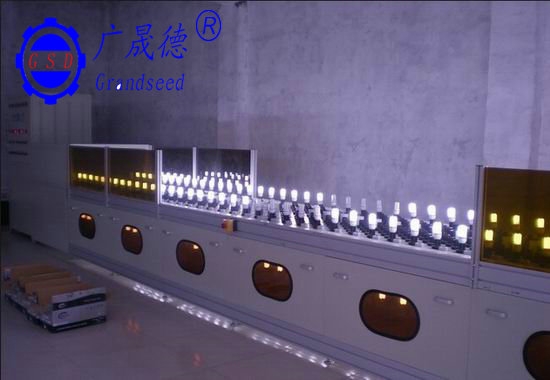

Description

Induction lamp aging line working video

1. Equipment structure: circular chain conveyor, sophisticated small trolley, frequency conversion speed regulation

2. Functional characteristics: This equipment is dedicated to the aging of bulbs and ballasts, through the aging of the high voltage and normal voltage areas of the bulbs and ballasts.

3. Material selection and production:

1. Power: Adopt "Jinfuling" 1.5KW variable frequency motor produced by Jiangmen Electric Company, WPSO/A60-100 type 1:400 reducer, YT/2HP frequency converter, variable frequency speed regulation, linear speed 0.2-2M/min can be used Tune.

2. Body frame: The frame is made of 40×40×1.5mm rectangular steel pipes, the head and tail guards of the body are made of 1.2mm cold steel plate, and the feet are equipped with galvanized adjustable feet; the body is 2 meters. .

3. Conveyor chain: C212A-inch double-pitch chain produced by Hangzhou Chain Factory, with a loop length of about 42 meters.

4. Old chemical station: the specification is 350mm×450mm. Each station is equipped with 1 AC10A energy socket (132 and regional plugs can be inserted) for the whole set of lamp loading and unloading; at the same time, it is equipped with E27 lamp holders for aging-type lamps. There is a conductive system under the trolley, which uses a special electric copper block to conduct electricity, and is equipped with a spark elimination system composed of a travel switch; at the same time, each trolley is equipped with a 6A short-circuit switch. There are a total of 95 small trolleys on the whole line (specifically subject to actual assembly). The whole machine provides a spare trolley.

5. Range of aging lamp: suitable for split square lamp with length≦423mm, width≦151, which is compatible with 85W-210W; suitable for split circular lamp with diameter≦337mm, which is compatible with 45W-210W; suitable for body lamp with height≦250mm .

6. Lamp and ballast installation method: The old chemical station adopts double-layer design and installation. The specific height of the upper and lower floors can be determined according to the customer's product. The design is designed to place the ballast on the lower layer and the lights on the upper layer.

7. Electric parameter detection method: use the multifunctional intelligent electric parameter tester provided by the external customer to detect, the detection interface is led out by the interface designed on the online body, and the specific locations can be freely determined by the customer.

8. Optical parameter detection method: use the external multi-function photometer provided by the customer, and use the probe (calculus sphere) of the test instrument to detect in parallel; at the same time, in order to ensure the accuracy of the test, the aging line should be stopped (stopped) during the test. The principle is that the photoelectric travel switch and the test time are adjustable).

9. Operation mode: This aging line provides two operation modes: continuous operation and cycle operation (the cycle time is adjustable). In order to ensure the accuracy of the test, the power-off time between testing and aging is required to be controlled within 3 seconds. At the same time, the customer's test station must be shaded to prevent damage to the eyes caused by the flicker of the light.

10. Operation area: The middle part of the online body is designed as an operation area, which is designed with 4 positions for upper light, 3 positions for lower light, and 3 positions for testing (the specific position can be customized by the customer).

11. Start-up area: In order to ensure the aging effect and test accuracy, it is designed as the start-up area after the operating station (lighting up): specifically 220V, 150V, 250V start (length is 8 meters).

12. Beat switch impulse zone: Design a 2-meter switch impulse zone, with adjustable impulse voltage (equipped with a voltage regulator with a voltage of 0-250V and a capacity of 3KW).

13. Insulation area: In order to achieve the function of heat preservation and shading, other areas of the whole line adopt an insulation layer. The inner wall is made of 1mm galvanized sheet structure, and the outer wall is made by bending and rolling of 1.2mm cold-rolled sheet. The insulation layer is made of aluminum silicate refractory fiber. 50mm.

14. Observation windows and doors: The two sides of the heat preservation area are designed to set up observation doors that can be opened every 2 meters, and an oval observation window is designed on the door. If defective products are found through the observation windows, the side doors can be opened to take out the defective products.

15. Daily output: The whole line can age 90 sets of lamps at the same time, 90 lamps can be aged out every 1 hour of operation for 1 week, and the daily output can reach 900 lamps per day in 10 hours.

16. Conductive system: equipped with conductive rails (made of 1.0 high-quality stainless steel) for conductive systems on each side of the side frame of the trolley, arranged along the two sides; the distance between the live line and the zero line of the conductive track is maintained at 60mm, and the track is suspended below the track design.

17. Sophisticated voltage zone: Designed as the upper and lower lights are not energized, the start zone (divided into 3 sections, the distance of each section is equal but the voltage is different: 3 sets of voltage 0-250V capacity 3KW voltage regulator respectively) and low temperature and low pressure area ( Configure 1 set of voltage 0-250V capacity 3KW voltage regulator) The rest is connected to the mains voltage in the aging area.

18. Electrical control: voltage and temperature control instructions adopt digital display type, the whole system adopts PLC and 7-inch touch screen control, and adopts 1 power distribution control cabinet to install. Equipped with an emergency stop switch on the body to facilitate the timely stop when the light is on.

400-0599-111

400-0599-111