menuProduct Center

backtrackYour locations:Home → Producs → Automated production line

Description

Guangshengde LED automatic panel light production line adopts a mode composed of multiple single machines connected in series

1. Through the online method, the principle of single machine plus total control is adopted, and the product is completed at one time. Once the machine fails, it will stop and not stop production.

2. Re-arrangement and planning of workshops, machines and equipment need to be moved and reassembled, which is simple, fast and convenient, and can be completed without the need for professionals.

3. Through the principle of dynamics, the mechanical structure adopts the method of synchronization and servo to achieve more precise movements.

4. Control system: It adopts a single machine + master control method, which can be connected with any MES system.

For detailed plans and cases, please contact Guangshengde

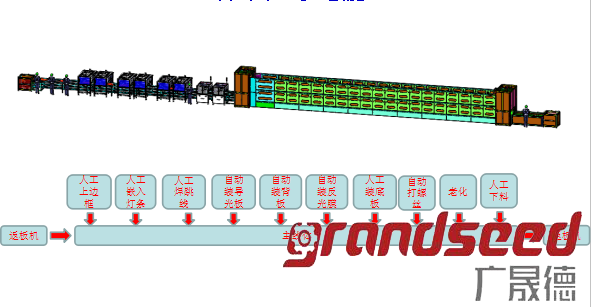

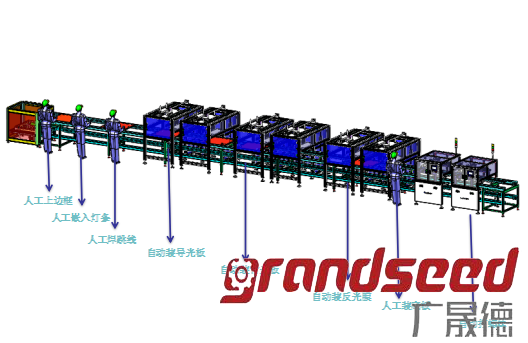

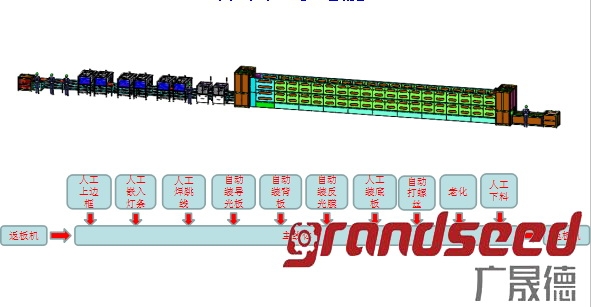

LED panel light automation production line scheme diagram

Guangshengde LED panel light automatic production line body is composed of: 22.4 meters double speed line, 0.8 meters upper and lower board return machine, secondary jacking positioning mechanism and electronic control. The main structure material selection and production and description:

1. Power mechanism: power adopts 2HP Yongkun gear reduction motor, V=10m/min (chain speed), sprocket 6', Z=13-17, active drive sprocket P=38.1, Z=9, bearing seat UCP208, cover plate & 1.2 cold-rolled plate bending forming, drive shaft ?45*560;

2. Tensioning mechanism: tailstock 40*40*&1.5mm square-through welding, tension screw tension, sprocket P=38.1, Z=9.

3. Frame: The frame adopts 40*40*&2.0mm square-through welding.

4. Guide rail: It adopts aluminum alloy guide rail 100*118 aluminum profile, and the surface is anodized.

5. Conveyor chain: triple-speed nylon low-noise chain P=38.1 (big black and small blue).

6. Small blocker: ?50mm*30mm single-acting cushioned cylinder is used, one for each station, when a tooling board enters, it will block a tooling board, and the blocker carrier board is made of 3mm thick steel plate.

7. Large blocker: ?30mm*30mm single-acting horizontal cylinder is used to reduce the impact of the tooling plate during operation. The cylinder is assisted by a stroke switch and a two-position three-way solenoid valve 3V210/220V control. The blocker carrying plate is made of 3mm thick steel plate. Finished, a total of 1 set.

LED panel light automated production line program

400-0599-111

400-0599-111