Troubleshooting of LED assembly line conveyor belt

2021-04-21(1322)Views

LED assembly lines can be used as transportation machinery and have been widely used in industries such as electronics, electrical appliances, and flour processing plants. When users install and use the LED assembly line, they are not very clear about the reasons for the failures that often occur, and there are not many ways to deal with them. Guang Shengde analyzed and explained the common failure causes and treatment methods of LED assembly line conveyor belts through this article.

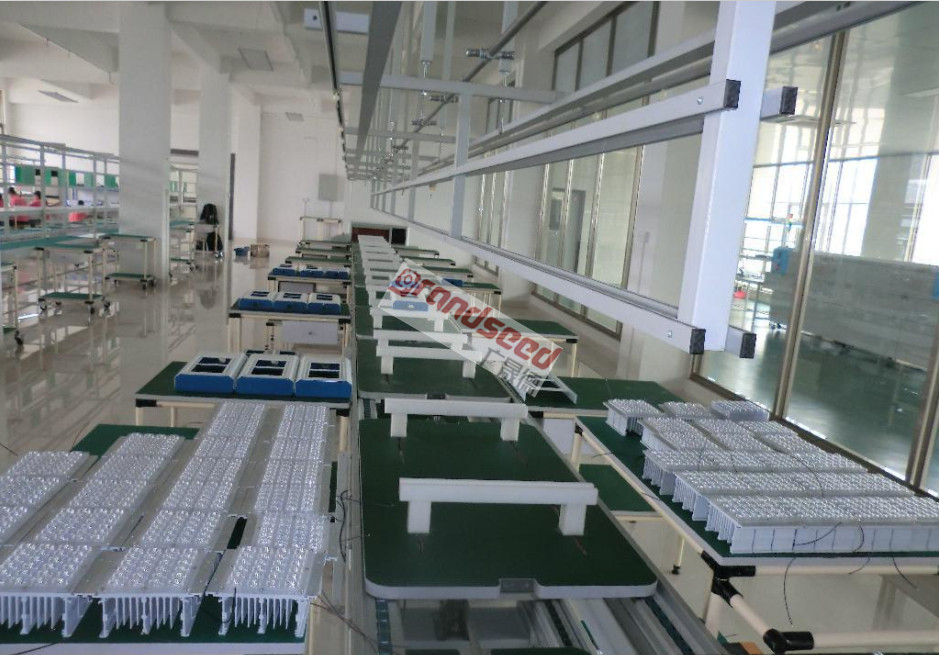

LED street lamp assembly line

1. LED assembly line conveyor belt slippage and solutions

During the operation of the conveyor belt of the LED assembly line, there are many reasons for slipping. The common causes and solutions are as follows:

1. The initial tension of the LED assembly line is too small. Insufficient tension at the conveyor belt leaving the roller causes the conveyor belt to slip. This situation usually occurs at startup, the solution is to adjust the tensioning device to increase the initial tension.

2. The friction between the drive roller of the LED assembly line and the conveyor belt is not enough to cause slippage. The reason for the rejection is mostly water on the conveyor belt or damp environment. The solution is to add some rosin powder on the drum. But be careful not to throw in by hand, and use blowing equipment to blow in to avoid personal accidents.

3. The rear roller bearing is damaged and does not rotate or the upper and lower roller bearings are damaged and do not rotate too much. The cause of the damage is that the tail floats too much, and the damaged or inflexible parts are not repaired and replaced in time, which increases the resistance and causes skidding.

4. Too fast start-up speed can also cause slippage. It can start slowly at this time. If a squirrel cage motor is used, it can be started after two jogs, which can also effectively overcome the slipping phenomenon.

5. If the load of the conveyor belt is too large, it will slip if it exceeds the capacity of the motor. The advantage of slip at this time is to protect the motor. Otherwise, the motor will be burnt after a long time. But for operation, it is a slip accident. To overcome the slipping of the conveyor belt, the cause of the slip must be found before effective measures can be taken.

Second, the deviation of the LED assembly line conveyor belt and its treatment

The deviation of the conveyor belt when the LED assembly line belt conveyor is running is a common fault. There are many reasons for the deviation, the main reason is the low installation accuracy and poor daily maintenance. During the installation process, the head and tail rollers and the intermediate rollers should be on the same centerline as much as possible and parallel to each other to ensure that the conveyor belt is not deviated or less deviated. In addition, the strap joints should be correct, and the circumferences on both sides should be the same. In the course of use, if there is a deviation, the following checks must be made to determine the cause and make adjustments. The frequently checked parts and treatment methods of conveyor belt deviation are:

1. Check the misalignment between the horizontal centerline of the roller and the longitudinal centerline of the belt conveyor. If the non-coincidence value exceeds 3mm, the long mounting holes on both sides of the roller set should be used to adjust it. The specific method is which side of the conveyor belt is deviated, which side of the roller group moves forward in the direction of the conveyor belt, or the other side moves backward.

2. Check the deviation value of the two planes of the bearing seat of the head and tail frame. If the deviation of the two planes is greater than 1mm, the two planes should be adjusted in the same plane. The adjustment method of the head roller is: if the conveyor belt deviates to the right side of the roller, the bearing seat on the right side of the roller should move forward or the left bearing seat should move backward; if the conveyor belt deviates to the left side of the roller, then The bearing seat on the left side of the drum should move forward or the bearing seat on the right side should move backward. The adjustment method of the tail roller is just the opposite of that of the head roller.

3. Check the position of the material on the conveyor belt. If the material is not centered on the cross section of the conveyor belt, it will cause the conveyor belt to deviate. If the material deviates to the right, the belt deviates to the left, and vice versa. When in use, the material should be centered as much as possible. In order to reduce or avoid the deviation of this kind of conveyor belt, a baffle plate can be added to change the direction and position of the material.

Latest News

-

Comparison of structural composition and advantages&disadvantages of automated assembly production lines

The automatic assembly production line is a system that asse...

-

Interpretation of the structural characteristics and accuracy for pick and place machine

Whether it is a fully automatic or a manual , whether it is ...

-

Grandseed LED Intelligent Equipment

Main business: Electronic integrated production line solutio...

-

Key points of wave soldering equipment operation

Wave soldering equipment is currently widely used automatic ...

400-0599-111

Hotline:400-0599-111

phones:138 2871 9992

Fax:0755-27315980

Email:gsd@sz-gsd.com

Address:Grandseed Science and Technology Park, No.177, Fenghuang Avenue, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen

400-0599-111

400-0599-111